sculpture

you are here [x]: Scarlet Star Studios > the Scarlet Letters > sculpture

July 4, 2011

clyde

by sven at 5:00 pm

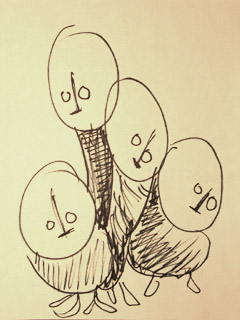

Happy birthday to my brother Shield! As a gift, I created this little goblin fairy, "Clyde."

If you scan back through my work, you'll see that I've been experimenting with wall sculptures for several years. And monsters… Since childhood. This feels like the next evolution for both. Very excited.

Clyde can be detached from the abstract painted backdrop panel. As an afterthought, I created an additional alternate wall mount, which focuses attention just on Clyde.

I think I kind of like the simple presentation better… But now Shield has both, and can pick whichever one works best for him.

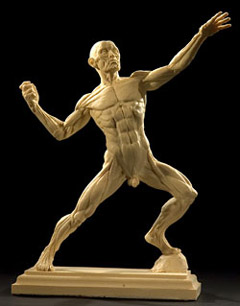

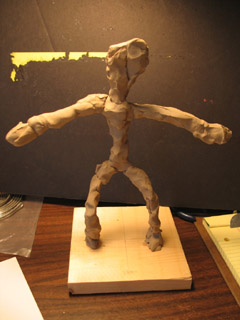

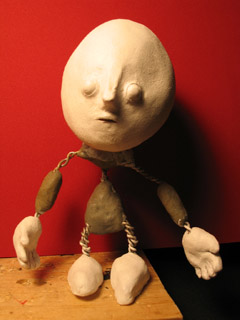

While figuring out what I wanted to do for this piece, I did some sketches in clay. I allow a lot of room for improvisation while sculpting — I thought you'd be interested to see how different the sketch is from the final.

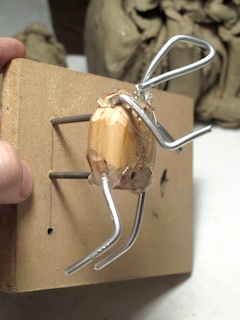

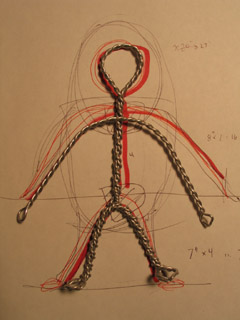

A big discovery on this piece: how to make a good core armature. I'm an armature guy — you'd think I'd already know what I'm doing. But armatures for stop-motion puppets and armatures for static sculptures are two very different things. Realizing that a simple block of wood on two steel posts makes a good core opens up whole worlds.

This armature isn't that great, actually. I was improvising, and didn't drill the holes for the rods perfectly straight. And I used hot glue rather than epoxy for attaching limbs. Still, the concept is there.

Super Sculpey (a polymer clay) needs to be fairly thin for baking. You bulk out the basic form using aluminum foil.

Here's the sculpture before baking or painting. After baking, I did a lot of work with sandpaper to smooth up the form.

I wound up spending a fair amount of time painting texture, highlights, and subtly different colorings for different parts of the body. Basically, though, the paint job begins with a dark base color, then proceeds to dry-brushing on the blue. It's a good way to make sure that crevasses are dark — instead of trying to paint them in with a tiny brush.

Here's what the back looks like with the two 1/8" dia. steel rods protruding.

I hope that Clyde enjoys his new life with Shield and his family.

And Shield: stock up on sugar cubes. I think this little guy has a high metabolism.

posted by sven | permalink | categories: painting, sculpture

May 25, 2009

new ceramic sculptures

by sven at 7:00 am

A while back I shared photos of some unfinished sculptures I'd made at Sara Swink's studio… Well, they're finally done! Some are painted, some are glazed. We'll start with the painted ones.

The mad scientist was the first piece I made at Sara's, and the first I tried painting with acrylics. It's based off of a photo of a man at a steel foundry, who was wearing a heavy silver suit to protect him from molten metal.

A lesson I learned here: clay loves watery washes of paint. Using the paint at full-strength kills detail and just looks wrong.

When I took Sara's class, this dancing duo seemed to be everyone's favorite. I mixed yellow with tar gel medium and glopped it on heavily to see if I could get some of the same textures as with the glazed pieces. …Nope.

Maybe encaustics could achieve the effect I was going for?

The whale critter was the last piece I made at Sara's. I was playing with wall-mountable characters… Unfortunately, it's weighted badly and doesn't hang right at all.

Next up, pieces that were glazed:

I really like the moon babi -- it feels like he has strong potential for being turned into a stopmo character.

The bat was the first piece I tried glazing, so I chose a simple black/brown. In general, I much prefer matte surface treatments to gloss. Too bad this turned out so shiny.

A little shout out to bat-fan Shu-Ju Wang… I can't look at this sculpture without thinking of you!

I'm really enamored with these three demon babis, which unexpectedly wound up being a set.

The little one feels fantastic in the hand. It sort of reminds me of the Venus of Willendorf.

In my mind, the series shows the evolution of a single being. The baby passes through this next phase on the way to its final form.

The glaze on the "molting" babi does this incredible crackle thang. I wish I knew how to simulate it using acrylics… I'm vaguely familiar with crackle paint -- but this stuff actually peels up into little platelets!

Whereas the baby has skin that feels like orange peel, and the adolescent is peeling, the adult demon's skin is creamy smooth. In all three cases, I painted on iron oxide, wiped it off, then put an essentially white glaze on top (3 varieties of white).

Exploring conceptart.org, it seems like a lot of sculptors fetishize wrinkles and skin textures… It's not hard to understand why. It's a lot of fun etching crevasses into clay!

Last night I created a wall mount for the adult demon… A perfectly rough and weathered scrap of wood with brass pins to hold the top-heavy beast in place.

I love the inherently gritty texture of clay, and the weight of it in my hand. It feels so real. Yet, even though clay is extremely cheap, the time spent waiting for it to get fired makes it more "expensive" than I initially figured. When I find the time, I'm planning on doing more experiments with home-bake polymer clay.

I really want to replicate the colors and textures of ceramic glazes, though. I've got some faux stone and "orange peel" spray cans to experiment with. I also need to explore a more neutral color palette. My natural tendency is toward vibrant colors… I think ceramics, as a species, gravitates toward earth tones.

posted by sven | permalink | categories: sculpture

February 11, 2009

learning ceramics with sara swink

by sven at 7:00 am

On Jan 17 & 18 I took a class from local ceramic sculptor Sara Swink titled "Two-Day Creative Process Workshop." Highly recommended!

Most of our time on the first day of the workshop was devoted to doing intuitive collages. Being familiar with the exercise, wherein you collect images without trying to figure out why they appeal to you, I decided to try a bold new experiment: collaging outward without boundaries.

I'm pleased with the end result... But not quite sure what to do with it now. Sara demonstrated cutting your collage into pieces and making a book with them. I can't quite bring myself to dismember the thing yet.

The point of collaging is to begin developing a "personal vocabulary" of images. On day two, we started with doodling exercises -- then moved into sculpting ideas from our collages in clay.

At first I was frustrated, because I didn't feel emotionally connected to what I was making. Two thoughts helped: (1) the idea that I could "doodle in clay" rather than trying to translate inherently 2D concepts to 3D; and (2) remembering that cel animators think about their characters in terms of underlying volumes, not just outlines.

Here's the first character I made that I felt happy with. "Babi" (pronounced "baby") is a reference to a drawing I did way back in high school. I'm not sure how to explain what "babis" are... They're generally blobby child-proportioned critters that live in the realm of dreams and the subconscious, hopping from one person's mind to another without anyone being aware.

The "babi" series that's emerged is very pleasing -- I'd like to see these characters turned into stopmo puppets.

I was attracted to the "creative process" class for a number of reasons...

I've never done much with water-based clay, and wanted to add ceramics to my skill set. Learning about clay with a sculptor rather than a potter seemed like the way to go.

I'm looking at clay as the sculptor's pencil: the fastest, cheapest way to rough out 3D ideas. I want use this medium for stopmo character development. Drawn sketches are useful, but not as illuminating as maquettes; Super Sculpey maquettes are too expensive to make en masse.

Also, as an artist, I'm very interested in process. This class, with its focus on developing one's "personal vocabulary" of images particularly excited me, because I feel like my analytical tendencies sometimes undermine connection to the content I'm developing.

Since the weekend class, I've gone back to Sara's studio for two more work sessions. My original seven sculptures -- plus an additional one from the following weekend -- have now been bisque fired. (That's the initial firing you do to make the clay hard and strong... Glazes are added in a second pass.)

For the sake of getting the full ceramics experience, I'm going to go ahead and glaze most of the pieces. This bust I made, however, is going to be painted with acrylics. If I wind up bisque firing clay character sketches in the future, I imagine I'll opt to just paint them, rather than glazing.

The bust was the very first piece I made, and I don't like it much. My second piece was this bat, which I like a good deal more -- but it still didn't really feel like "me" when it came out. It's going to be a wall-hanging with a black-brown glaze.

(Every time I look at the bat, it makes me think of Shu-Ju Wang -- a local book arts friend who's very into our nocturnal, flying companions.)

Sara has ongoing drop-in classes on Saturdays, where you get individualized attention and can work at your own pace. For a while, it looked like I'd be going directly from my Saturday morning playwriting classes over to Sara's studio....

Unfortunately, I'm feeling very pinched for time now, so ceramics work is going to have to be sporadic for a while. Even so, I'm really glad that I grabbed the opportunity to take the process class when I had it. Very inspiring -- I strongly recommend taking it if you have the opportunity.

posted by sven | permalink | categories: classes & workshops, sculpture

July 6, 2007

"pajama dreamer" at 100th monkey studio

by sven at 9:15 pm

My 3D collage "pajama dreamer" is hanging in a gallery this month... It was selected for inclusion in the 100th Monkey Studio's "First Annual Men's Show."

The show opened tonight, and runs until July 31st. If you want to check it out, 100th Monkey is at 110 SE 16th Ave @ Ankeny.

Huge thanks to Gretchin, who suggested that I submit, and then managed communication with 100th Monkey for me. I am extremely grateful for this help! Consumed as I am with getting Let Sleeping Gods Lie done, I'd never have considered submitting to a show right now -- were it not for Gretchin's generous offer to take care of the details. Thank you!!

posted by sven | permalink | categories: exhibits & events, sculpture

January 15, 2007

casting a resin head

by sven at 8:00 am

Friday was a "stopmo play day"... I put the newly renovated studio to good use, exploring mold-making and casting.

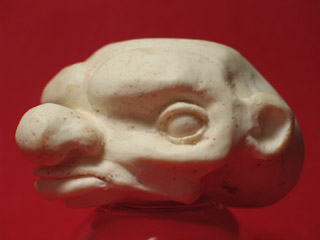

Back in early December, I had a spare hour or two after helping Gretchin with prep for one of her holiday sales. So I pulled out some "Chavant NSP - Medium, Brown" and sculpted this head.

I cleaned it up just a little bit on Friday, smoothing the surface with Brylcreem and a paint brush.

Here's some of what was going through my mind:

Just before Thanksgiving I had a little breakthrough, some insights about character design. Working in my sketchbook, I made rows of circles -- each one a blank face -- and then tried varying the facial features systematically.

Do I like big, medium, or small eyes the best? Do I like the eyes to be close to the nose, centered, or out toward the ears? Do I like the eyes to be high on the head, in the middle, or down around the jaw? ...Pages of variations like this gave me a much better sense of what sorts of characters I want to be creating.

This head was attempt to take some of those sketches into the third dimension.

Also, during the past month or so, I've been putting some energy into studying anatomy. I learned a good deal when I was taking that sculpture class with Kim Graham last summer. I've now picked up some anatomy books, and have been making practice sketches of skulls and skeletons. I figure, the more anatomy you can put into a sculpt, the more realistic/plausible-looking your result will be.

The head was sculpted without an armature. For the sake of making a mold, I put it on a piece of 3/16" brass rod, and fixed that into a piece of wood.

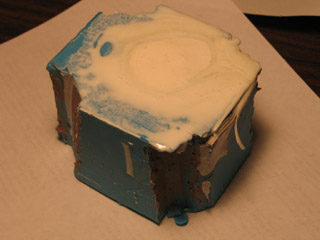

To make a mold box, I cut out pieces of foamcore and used hot glue to seal the edges together.

For this one-day project, I wanted to get my hands dirty -- and not get stuck over-thinking it. I knew at the outset that this might mean some significant screw-ups. But oftentimes getting a feel for mistakes gives you an even better grasp of how to do things right later on. So, I was prepared to see how things would go wrong.

Case in point: When I opened up my container of silicone base, I didn't have as much left as I'd remembered. I hastily put some wedges of clay into the mold box to take up space -- just hoping that I'd have enough silicone for the mold then.

I'm using silicone from TAP Plastics. Why TAP? Because they have a storefront in town where I can browse, instead of having to buy online.

It took two batches of silicone to fill the box. The first was just silicone base plus the quick cure catalyst (6-8 hour demold time). I thought I'd try the trick where you make a hole in a paper cup and drizzle the silicone into your mold -- the idea being that the string of silicone will break up bubbles. The silicone was so viscous, though, it didn't really want to cooperate. It didn't really even want to fall out of the hole.

So, for my second batch, I mixed in 10% silicone thinner (which also functions as a filler). This poured a good deal more easily -- but at this point I forgot to try the hole-in-the-cup trick.

The silicone just barely managed to cover the head.

Silicone cures via a chemical reaction between the base and the catalyst. As such, it can be speeded up by adding heat. I've tried this with good results using DragonSkin. I decided to try it with the TAP silicone.

This one of those mistakes I alluded to earlier...

I put the mold in the oven on an old pizza pan. [We've dedicated the oven in the studio kitchen to chemical play.] The oven only goes as down to 170 degrees, so I had to prop open the door to take it lower. You can cure DragonSkin in 30 minutes at 150 degrees. I was indecisive and varied the temperature between 130 and 150 degrees during the baking period.

I left the mold in the oven for 2 hrs 15min -- and probably could have taken it out sooner. When I retrieved it, I discovered that the hot glue had melted and the mold walls had popped open. The clay space-fillers looked nearly liquified. ...And yet, the silicone mold itself seemed pretty OK.

[The top has a slight tackiness to it -- which I attribute to the silicone thinner. The sides are properly dry.]

When you make a puppet body out of DragonSkin silicone, you're baking the silicone inside of a plaster mold. Nothing's going to melt. ...So, while I proved to myself that I could successfully speed up the curing time of a silicone mold by adding heat, I also discovered that this is inappropriate when your original is made out of oil-based clay and your mold box is made of materials that melt at low temperatures.

Surprisingly, the silicone took a pretty good impression -- even with the clay liquifying. However, because the clay head got melty, it left a lot of residue on the interior of the mold. I cleaned it out with an old paint brush and isopropyl alcohol -- but I still couldn't get every fleck.

The original clay head was demolished because I put it into the oven. Next time, I think I'll put it in the refrigerator or freezer before pouring the silicone, and then just let the silicone cure at room temperature overnight.

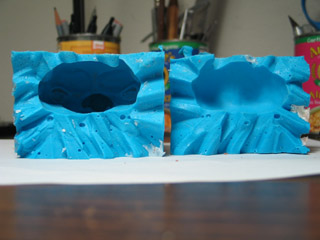

OK, now that the mold is made, it's time to make a casting.

I used TAP Quik-Cast Polyurethane Casting Resin, and mixed in microspheres to make the casting more lightweight. The pour hole is where the brass rod used to be; I enlarged it into a funnel with an X-Acto blade.

In terms of gooeyness, silicone is like slightly liquified peanut butter. Simply dreadful. Resin, on the other hand, pours very easily. It went through the pour hole without incident.

However, I didn't bother to drill a hole in the mold for air to vent out of -- so I did have to awkardly tip the mold around a lot, trying to get bubbles to come out.

Despite all the mistakes I made, I got a surprisingly good casting out of this mold.

Because the silicone wasn't properly degassed, there were a lot of bubbles in the mold. The resin faithfully reproduced these bubbles in the casting.

When I cut open the cured silicone, I tried to use a jeweler's cut -- making a zig-zag cut with an X-Acto blade. I was a little disappointed with the results. I got quite a bit of flashing along the split-line -- particularly at the top, where the silicone was too thin.

The resin seems to have cleaned out the remnants of clay left inside the mold. So, I've got a half-decent mold to play around with some more now.

I'm thinking that I want to try a hollow casting. I've seen this done in puppet animation to get a very lightweight head.

I'm also considering adding a venting hole in the chin. When I'm pouring resin, the chin is the highest point inside of the mold, and a big air bubble gets trapped there.

I didn't realize it immediately, but the casting actually came out with a hollow chin. As everything cooled off, the chin kinda shrivelled up. Now it looks like the head doesn't have a jaw at all.

Oh well. Plenty learned.

posted by sven | permalink | categories: sculpture, stopmo

June 14, 2006

setting up a small machines shop

by sven at 1:00 am

I'm actually doing it: I'm setting up a small machines shop!

I've just ordered three vital tools: a mill, a lathe, and a drill press.

In my initial research on milling machines it looked like I was going to go with a MicroLux. However, that machine's 110 pounds... I just can't accommodate it in my work space. And certainly not if I'm going to have other machines, too. What I need is a group of small machines.

For a long time I kept trying to find a way to avoid purchasing multiple machines. I've finally accepted that the mill, lathe, and drill press all have their own specialized functions. It's like a kitchen: an oven, a stove, and a kitchen mixer all serve different functions... You can get by without them -- but, oh!, the things you can cook up when you are fully equipped with proper tools!

What do these machines do?

A drill press drills perfectly vertical holes; it's quick and easy to plunge the drill bit into your work piece.

A mill allows you to shave metal off of a work piece that is held still. Although it looks a lot like a drill press, the mill is designed to take sideways stress that would break a drill press (and take out your eye in the process!). A mill is designed to do very, very precise work; it's not the best tool for just drilling a quick hole.

A lathe is like the opposite of a mill: instead of holding the work piece still and cutting it with a spinning tool, the work piece is what spins while the cutting device remains still.

...With luck, the machines that I've just purchased will be the only big purchases that I ever need to make for metalworking. And, if I understand the relative sizes of these machines, they should all fit on one table.

There's a lot of learning still to do, about how to properly use these devices -- but it seems to me that 90% of making metalworking projects is just having the appropriate tools available. And now, I'm going to have those tools.

Exciting! Intimidating! Liberating!

posted by sven | permalink | categories: sculpture, stopmo, studio space

June 5, 2006

making my first two-part mold

by sven at 7:54 pm

Thursday (June 2) I got back into the studio and made my first two-part mold.

The mold itself is made from ultracal 30 that I bought at Stephenson Pattern Supply. Ultracal is a gypsum product that's about halfway between plaster and concrete; it's designed to capture a lot of detail.

The red clay is "cherry creek red (no grog)" that I bought at Georgies. I needed a soft clay that wouldn't damage my sculpt; an employee recommended that I select any "low fire" clay without grog. I picked a red clay so there'd be good visual contrast with my sculpt while I was working.

This sculpt has a long nose and long feet. It really ought to get a three- or four-part mold. However, I opted to go for a two-part mold.

Why? I decided that I just couldn't leap from only ever having done one-piece molds to doing a complicated four-piece mold. The material I'm going to use for casting is flexible; I'm hoping that with a little effort I'll still be able to get it out of the two-piece. ...I decided that while this is most likely a mistake, it's a mistake that I need to make in order to understand the mold-making process better. I also decided that I've been being too precious with my sculpt; there will be more sculpts -- it's OK to screw this one up.

I think occasionally it's worthwhile to go ahead with a project even when you know at the outset that it's flawed. Mistakes are an important part of how we learn.

I made a cardboard wall to hold the liquid ultracal in place... I've watched Kathi Zung's video, and she doesn't do this. She slathers the material on by hand, then shapes it with a kidney-shaped pottery tool (sort of like frosting a cake).

It may well be that I wasn't mixing my ultracal thickly enough -- or maybe I should have waited for it to get stiffer before pouring... Nonetheless, the technique I used seems to have worked out alright.

For making "keys" for the mold, I tried two different styles. On one side there's a sort of clay trapezoid with tapered edges. On the other side there are two marbles that I pressed into the clay. Initially, the marbles didn't want to separate from the ultracal 30. A gentle knock with a hammer did the trick, though. ...The two sides of the finished mold seem to fit together very well.

I extended the top of the mold using what was at hand: cardstock. It worked OK when the paper didn't have to hold back too much ultracal.

I figured out when I made my second wall that you really do need the cardboard for strength -- but if you line it with cardstock, then the resulting mold has smoother and nicer sides.

When I mixed the ultracal 30 with water, I did so in these big paper buckets that I found at Ace Hardware. They seem to be meant for house-painters... However, they very quickly became soggy. Near the end of the day, I was carrying one of these paper buckets, full with water, away from the sink -- and it started gushing water out the bottom onto the carpet!

Grrr.... No real harm done -- but on my next plaster-making run, I'll definitely be using plastic buckets instead.

When the ultracal for the first side of the mold was hard, I removed the cardboard walls. Then, I flipped the whole thing over and stripped away the red clay. I had been worried that the clay would damage my sculpt... I was very pleased to discover that it really left no damage at all.

When I was flipping everything over so I could do the other side, I had an absentminded moment where I tried to pick up the work-piece by its wooden base. Oops! While it looks like everything is firmly attached to that piece of wood, really it's just the sculpt that's held in place with tie-downs. My flub created some tiny spaces beneath the feet of the sculpt that I had to fix -- otherwise, ultracal would have flowed into the feet-holes of the mold.

There were some minor smudges of red clay left on the sculpt. It was very easy to clean these off, just using a brush and water.

After I cleaned off all the red clay residue, I used a brush to apply vaseline to the ultracal. In retrospect, I think I probably should have applied vaseline to the sculpt as well. It was a nightmare picking plasticene out of the mold later.

Doing the second pour of ultracal is pretty similar, so I'm just going to let the pictures tell the story here...

After giving the second side of the mold time to harden, I opened it up... The sculpt didn't survive at all. I had thought that plasticene -- an oil-based clay -- wouldn't stick to the ultracal. I was wrong.

Maybe I opened up the mold too soon. I know that you're supposed to let ultracal set for at least two hours -- and I only gave it one. When I opened it up, it was pretty warm inside... The plasticene had the consistency of peanut butter. Maybe if I hadn't been in such a hurry -- if I had let everything cool down -- maybe then the plasticene would have come out more easily.

Or maybe I just needed to apply a release to the sculpt itself. Vaseline would probably work. I've also heard that a clear acrylic spray can do the trick.

(Here you see those terrible buckets that I mentioned earlier.)

Even after I'd scraped all the plasticene out of the mold using my trusty loop tool, there was still an oily residue. To get this out, I needed a solvent. What I had at hand was turpenoid. Scrubbing turpenoid around with a brush, the residue came out quite easily (although scrubbing ultimately ruined the brush).

...I'm a bit worried, though. Turpenoid is a petroleum distillate. Will it leave any sort of oily residue? When you cast liquid latex in a plaster mold, it cures because the ammonia content is absorbed into the gypsum. Will a petroleum residue prevent the ultracal from absorbing the ammonia? Or will the turpenoid, since it's a solvent, evaporate from the mold -- leaving it OK for use with latex?

And here's the finished mold! I took me a bit over eight hours to make -- kinda a long time, but not over my patience threshold.

Boy is this thing massive, though! Lesson learned: Another advantage of doing a three- or four-part mold would be that you wouldn't need nearly as much ultracal.

THE SURPRISING EPILOGUE

The mold is done; I'm ready to make castings. However, just this morning I had surgery on my back to remove a lipoma (a large, non-cancerous fatty deposit). Consequently, I'm not supposed to lift anything as heavy as a gallon of milk for 4-6 weeks. How am I going to work with my monster-sized mold?

Gretchin has generously offered to help... Still, I'm having a moment of discouragement.

posted by sven | permalink | categories: sculpture, stopmo

May 24, 2006

if i buy a milling machine...

by sven at 8:00 am

I very much want to build metal-jointed armatures for my puppets. I've come up with a relatively simple brass design that can be made with handheld power tools. However, I'm interested in graduating up to making steel and/or aluminum armatures. Ones with joints that make sense for the anatomy: e.g. knees that only bend on one axis of rotation.

That probably means: buying a milling machine.

I've been doing a lot of research. At this point in time, I think that I would choose to buy a MicroLux Mini Milling Machine from Micro-Mark for $590 (that's including shipping). However, I haven't fully committed to buying any machine -- not just yet.

For my own sake, I need to summarize what I've learned so far...

1. CROSS SLIDING VISE?

A while back, I bought a drill press at Home Depot -- which I returned a few days later. ...Immediately after leaving that Home Depot, I stopped at a hardware store that I'd never been in before: The Tool Peddler (9907 SE 82nd Ave). Inside, I discovered this tool I'd never seen before: a cross sliding vise. The cross sliding vise looked very much like the X/Y table on a milling machine. It made me wonder: can you use a cross sliding vise to turn a drill press into a milling machine?

I posted my question on SMA. The answer I got back was that a drill press isn't really built to deal with the sideways stress. Mike said that the machine will vibrate and give you sloppy cuts. Nick said that he's tried using a drill press to mill aluminum (which is soft) and failed. Jon Frier warned me that he had tried milling with a drill press -- and has scars from the attempt!

I went back into the store to have a second look at the vise, and was told similar things by an employee: the cross sliding vise is really just for precision-positioning. You might be able to use it for milling wood -- but trying it on metal would be a Bad Idea.

2. PRICES

For making armatures, you don't need a full-sized milling machine. There are "micro" mills and "mini" mills -- and either of these sizes will suffice. In general, it seems that micros cost more than minis -- you're paying for miniaturization.

From what I've read, it looks like a good mini is going to cost at least $500, and a good micro is going to cost at least $650. The price range for minis I've looked at runs from $399 to $525. The micros fall into two groups: $240 to $260, and $650 to $995. All of these prices are without shipping. Also, these are prices for the machines only -- milling bits, clamps, or other accessories all have to be purchased separately.

Micro mills I've looked at:

- Procon = $240 ($375 with milling table?)

- Harbor Freight = $259.99

- Sherline = $650 / $775 / $995

- Taig = $680

Mini mills I've looked at:

- Cummins = $399

- Procon = $405

- Harbor Freight = $459.99

- Micro-Mark MicroLux = $524.95

- Grizzly = $525

The Harbor Freight micro milling machine seems to be the cheapest milling option available. Unlike the Procon (whose price is unclear), I can buy it locally and avoid shipping costs. However, it's remarkably heavy for a micro; its X/Y table is quite small; and it only has two speeds. The cheapest option is worth mentioning -- but I think I would have more confidence purchasing one of the fancier machines. We're going for precision metalworking here. (And "you get what you pay for.")

3. WEIGHT AND SIZE

For me, weight and size have probably been the most significant consideration after cost. My studio space is a spare bedroom. I don't have a proper metalworking shop -- and I don't have a lot of free space. This would seem to indicate that I should get a micro mill.

Comparing height, width, and depth is cumbersome (even for me!); a comparison of weight should give an adequate sense of how big these things are...

Micro mills I've looked at:

- Procon = 15Kg without table (33 lbs.)

- Harbor Freight = 103 lbs.

- Sherline = 33 lbs. / 36 lbs. / 38 lbs.

- Taig = 65 lbs.

Mini mills I've looked at:

- Cummins = over 150 lbs.

- Procon = 40Kg (88 lbs.)

- Harbor Freight = 150 lbs.

- Micro-Mark MicroLux = 110 lbs.

- Grizzly = 153 lbs.

If weight and size are the primary considerations, then Sherline is the clear winner. Reading through the setup instructions, I see that you do need to attach the Sherline mill to a board, to create stability -- but you don't need to (and shouldn't) secure it to a workbench. It appears that all other mills (including the Taig) need to be bolted to a heavy table.

4. STRENGTH

The strength (or "beefiness") of a mill seems to be a matter of two factors: (1) what kind of metals it's able to cut, and (2) how rigid the milling column is.

On two threads over at SMA, professional armature fabricator Lionel Ivan Orozco ("LIO") advises that the extra mass and power of a mini mill (vs. a micro) can be advantageous.

LIO uses a Grizzly mini mill (as well as a 400+ Lb. Enco!) -- however, he's quick to point out that with intelligent design, there's still a lot that one can do with a micro.

Tom Brierton, another professional armature fabricator, gets good results with a Sherline. In his book Stop-Motion Armature Machining: A Construction Manual, Tom says

"Sherline miniature mills and lathes can cut the following metals quite easily: all grades of aircraft aluminum, brass, and mild to semi-hardened steel, such as the 303 and 404 series steels. Anything beyond the hardness of 440 will require very specialized cutting tools and jobber drill bits, which are very expensive. It has been the experience of the author that rarely is there a need to go beyond the 440 hardness when building stop-motion puppet armatures, as these metals are quite sufficient for armature purposes." (p.21)

...So, it appears that the Sherline is limited in terms of what materials it can deal with -- although it's unlikely that you'll need metals that it can't cut -- not within the realm of stopmo. Still, it's worthwhile to realize that size does limit the versatility of the Sherline.

[As I'm reviewing this portion of Tom's book, I now see that he says "Sherline machines must be securely mounted on a table, preferably with screws and bolts." This seems to contradict what Sherline says on its website.]

With regards to rigidity, the difference between a Sherline and a Taig is visible in their photographs.

Look at the milling column of the Sherline...

Now look at the milling column of the Taig. You can see that it's much more solid. ...The Taig website boasts about their micro mill's strength:

"This is the machine you don't have to baby. The Micro Mill is a rugged precision instrument that has plenty of rigidity. Its machined, ground and stabilized steel bed has a life-time ball bearing spindle, coupled with a six speed positive vee belt drive. Spindle speeds in geometric progression from 525-5200 RPM (CR version 1000 - 10000 rpm) provide the power to "HOG" 1/8 inch cuts in mild steel or the speed and precision to "dust" a few tenths (compare that to other mills of similar size on the market, you can't!)."

It appears that if strength is the primary concern in choosing a mill, then the Taig wins out over the Sherline. However, a Taig pretty definitely has to be screwed down onto a workbench -- so at that point, you might as well go for a mini like the MicroLux.

5. MINIS VS. MICROS

There a few differences between the minis and the micros worth mentioning...

(1) The milling heads on the micros can turn 90 degrees in either direction; the milling heads on the minis can't turn -- but their milling columns can turn 45 degrees in either direction. It sounds like this is a point in favor of micros -- however, after asking folks on SMA and looking in Tom's book at how specific armature joints are made, I find that you probably want to avoid tilting the milling column entirely. It's unnecessary -- and "tramming" the column to make sure it's perfectly vertical sounds like a very tedious process.

(2) The minis can double as drill presses -- the micros can't. The minis all have a wheel on the side that allow you to easily plunge a drill bit into a work piece; the micros can only lower their drill bit slowly, using very small increments of movement. Getting two machines for the price of one -- both a milling machine and a drill press -- seems like a significant benefit to me. [Correction: It appears that the Procon and Harbor Freight micro mills can double as small drill presses.]

6. COMPARING THE MINI MILLS

An interesting fact about the minis is that at least five brands are all made at the same Chinese factory: Grizzly, Harbor Freight, Micro-Mark, Homier, and Cummins. LittleMachineShop.com has a very useful comparison chart for these five brands. [I have been unable to find any info for Homier Mobile Merchants' "Speedway" model, and have thus excluded it from consideration.] Procon appears similar to these brands, but seems to be produced in a different factory.

Now, on to comparing the various brands of mini mills with one another...

The Procon website is confusing -- and as I am looking at it today, the link to its page about mills seems to be broken. The Procon also appears to be a metric machine. I'm disqualifying it from my considerations.

The Cummins ($399) and Harbor Freight ($459.99) both seem to be somewhat less expensive because they have only two speeds. From what I read, being able to control the speed at which you mill each particular kind of metal is very important. Having only two speeds is a significant deficit. However: There are at least two Harbor Freight stores here in Multnomah county; all of the other brands seem to only be able via mail order. Thus, Harbor Freight gets some extra points... With their brand, I wouldn't have to pay shipping costs.

The Grizzly ($525) and the Micro-Mark MicroLux ($524.95) are essentially identical in price -- and even when shipping is considered, they only differ by $5. The Grizzly is heavier: 153 lbs. versus 110 lbs. The MicroLux's lighter weight should probably be considered as a point in its favor.

The tipping point in favor of the MicroLux may be that it has "true-inch" feed screws and dials. As the LittleMachineShop.com comparison chart explains,

"The MicroLux mini mill has one unique feature; the table feed dials both advance 0.050 inch per revolution. On all the other mini mills the dials advance 1/16 inch per revolution. The 0.050-inch per turn is easier to use than the 0.0625-inch per turn of the other mini mills. Micro-Mark will have you believe that the other mini mills have metric dials, but they do not."

I've looked at the Harbor Freights dials in person and can attest: .0625-inch per turn is really strange-looking and counter-intuitive. It's difficult to explain; suffice it to say that I walked away from the store not understanding how one would actually work that dial.

So, when it comes down to it, it looks like both the Grizzly and the Microlux are very good machines. LIO has a Grizzly. And, I feel it's worth mentioning, Kevin Kelly's "Cool Tools" website advocated for the Grizzly (though not in comparison to anything else). On the other hand, both Yuji and Eric Scott over on SMA have opted for the MicroLux, and seem very happy with the machine. ...For someone who's not a pro like LIO, it sounds like the "true-inch" dials make the MicroLux slightly easier to work with -- giving it a slight edge.

7. PICKING THE MACHINE FOR ME

It seems that my first choice for a milling machine would be the MicroLux ($524.95). It's strong: having both rigidity, and the power to cut different metals with ease. It's versatile: being able to serve both as a milling machine and a drill press. It's somewhat easier to use than other mini mills: having both a variable speed control, and "true-inch" dials. It's less expensive than the micro-mills. And at 110 pounds, it's not light -- but it's also not completely unmanageable.

The "big" problem with the MicroLux is that it commits me to also buying/making a sturdy workbench that it can be screwed onto. So, my second choice for a milling machine would have to be the Sherline Model 5400 Deluxe Mill ($775).

...The basic Sherline mill (Model 5000, $650) is a bit smaller than the Deluxe -- but also lacks the "laser engraved scales on the table and base" -- which seems a little unreasonable. Having an incremented ruler built into the X/Y table feels essential; the Model 5000 seems inadequate. The high-end Model 2000 ($995), on the other hand, seems like over-kill. The "Deluxe" seems to be Goldilock's "just right" compromise.

[Note: As I double-check info now, it appears that the Model 2000 may be the only Sherline with a milling head that can turn 90 degrees -- the others seem to be fixed in place.]

A Sherline is the most lightweight option. There is conflicting info, but it appears that one can merely attach it to a wooden tray -- which then allows one to put it away when it's not being used. It has variable speed -- whereas the Taig has only six speed settings, and the Procon and Harbor Freight micro mills only have two. Sherlines are the best documented of all mills (micros and minis) that I've seen, and there's a vibrant online community of users.

Really, I think the only sticking point that's really preventing me from buying a MicroLux right now is: "Where am I going to put it?" ...I'm having trouble imagining where I want to put a heavy workbench.

That makes me begin to wonder if the Sherline might be the better option after all. BUT... It's more expensive -- by $250 -- and I have to remember that there's bits, clamps, and accessories to buy, as well as the machine itself. And it's also helpful at this point to recall what Yuji said while discussing his purchase:

"I chose the mini mill and lathe because I wanted something beefier than the Sherline. I got to use Sherline equipment with Tom Brierton last year when he gave a workshop here in Los Angeles. I thought they were good little machines but there were too many little things I didn't like about them too. Now that I have been working on my Micro Mark machines for a few months, I am very happy. And the fact they are cheaper, well that's just icing on the cake."

Yuji's kind of vague -- but his comment does help me feel more confident about going for the MicroLux.

SO! I guess the question I'm left with is: what am I going to do for a workbench?

8. THE WINNERS

This post is long and rambling, so let me summarize in another way. In the "small affordable milling machines" competition, I'd like to announce awards in three categories:

- cheapest machine: the Harbor Freight micro mill ($259.99, if bought locally)

- strong and versatile: the Micro-Mark MicroLux mini mill ($589.95, shipping included)

- small and portable: Sherline Model 5400 Deluxe micro mill ($775, shipping not included)

...And the winner for best overall value: the Micro-Mark MicroLux mini mill ($589.95, shipping included)

posted by sven | permalink | categories: miscellany, sculpture, stopmo

May 23, 2006

the drill press mistake

by sven at 8:00 am

It seems like there's a progression of complexity for puppet armature designs:

- Mike Brent: aluminum armature wire, epoxy putty bones, nuts for tie-downs

- Nick Hilligoss: aluminum armature wire, wooden body block, T-style tie-downs

- Susannah Shaw: aluminum armature wire, K&S plug-in limbs

- Lionel Ivan Orozco ("LIO"): "open-hole double-ball" joints made from steel strips, bearings, and rods.

- Tom Brierton: multiple types of joints, milled from aircraft aluminum stock

I've gotten to the point where I can make a Susannah Shaw design pretty comfortably. For a while, I thought it was reasonable to just take the next step up -- getting only what I would need in order to make a LIO armature... That meant: a drill press, and some special-order metal stock.

About two months ago, I actually went ahead and bought a drill press. I was reading and re-reading LIO's tutorial on how to drill type 302 stainless steel balls. In the photos, he uses a 10" Ryobi drill press. I could see in Nick Hilligoss' tie-down tutorial video that he uses a Ryobi bandsaw. Ryobi seemed like a trustworthy brand. Affordable, too: the 10" drill press only costs $99 at Home Depot. After coveting it for weeks, I finally decided that my ultimate purchase was a foregone conclusion, and that I might as well quit putting it off.

However, I wound up taking the drill press back just a few days later -- never even having taken it out of the back of the Svan.

Reason #1

At the point of purchasing a drill press, you enter into the world of tabletop machines -- which take up quite a bit of space. If a milling machine were able to both mill and drill, then perhaps for the sake of space I ought to just save up and get the more versatile machine.

LIO ranted a little at me that a drill-press is an essential tool in any shop. That helped goad me into purchasing the drill press. He's an authority that I respect... But did I feel like I truly understood why I need both tools? No. So I decided I should take the drill press back. I can always re-purchase it later, if I finally understand why both are necessary.

Reason #2

I realized that I just didn't know enough about machining metal yet. I was depending entirely upon other people's tutorials and advice. When I'd ask a question on SMA, I could see my own ignorance reflected back in what I wrote, and it just seemed ridiculous.

My new resolve: I'm a smart boy -- I can own the knowledge of metalworking for myself -- no more dumb questions -- go forth and read up on the subject! So, I drove to Powell's Technical Books and purchased The Home Machinist's Handbook by Doug Briney and Tabletop Machining by Joe Martin (owner of Sherline).

Research research research....

posted by sven | permalink | categories: sculpture, stopmo

May 22, 2006

learning metalworking

by sven at 8:00 am

[Last week I wrote a comment over at Shelley Noble's "Notes from Halfland" blog that seemed worth re-posting here. I have thoughts about fleshing it out into an illustrated tutorial -- but best to share it as-is for now.]

Prior to February, I had never done any metal working. Period. In fact, I clearly remember the message I wrote to Mike saying how the thought of metalworking scared the bejeezus out of me. His encouraging words got me over the hump, to the point where I decided that I'm probably a smart-enough sort of person to be able to get the job done. [THANK YOU MIKE!!]

There were several distinct steps for me in learning what I know so far.

#1. Cutting a strip of aluminum. I started with a hacksaw and trying to hold the metal down by hand. Couldn't do it. I got a drillpress vise -- wrong kind of vise. I got a small clamp-to-the-table vise and wax for the hacksaw blade. That worked, but my cuts were sort of crooked. I tried using a dremel cut-off wheel, and suddenly cutting metal was like slicing butter.

#2. Drilling and tapping a brass strip. Drilling was pretty easy right off the bat. What I didn't realize at first was that normal drill bits work fine. If they're labeled HSS, that means "High Speed Steel", which can easily cut the softer metals (brass, aluminum, copper). HSS bits are probably what you have by default; you can get carbide bits at a hardware store, which are even more durable. ...Tapping just requires buying a little specialized tool so you can screw threads into a hole. I was so proud when I showed Gretchin a simple hole with a screw in it -- and I had made the threaded hole myself!

#3. Soldering. I needed to learn soldering so I could attach little brass nuts onto square K&S tubing, so I could make plug-in armatures like Susannah Shaw describes. (Neither super glue nor epoxy putty made adequate bonds.) My first frustration was learning that a zinc nut wasn't going to attach to the brass K&S -- it had to be brass-to-brass. I discovered that I had to sand the parts a little to make sure that they were clean. Then it took a little bit of fiddling to figure out where to press the soldering iron and how to hold the soldering wire effectively. ...But then, poof! I knew how to solder!

#4. Safe ventilation. Reading online, I found out that the fumes from soldering -- both from the lead and from the rosin core -- are hazardous. (My other main worry had been the fumes from epoxy glue.) My desk isn't in front of a window, so I needed a way to suck the fumes through dryer ducting that I bought at Home Depot. I tried an air brush spray booth -- it was way too big for my desk! I found some tiny desk fans made specifically for soldering and ordered one from Amazon.com. I figured out a way to modify it so it could vent through the ducting. The write-up on my solution is available over at Scarlet Letters.

#5. Using a torch. When it came time to attach balls onto rods, the soldering iron couldn't get the metals hot enough. I wound up using a butane micro-torch -- actually the kitchen brulee torch that I got two Christmases back! Flame scares me, and it took a little time even when I was in the kitchen to get comfortable with using something that's 1200 degrees hot. Using it for metal working, it wasn't bad at all -- as soon as I figured out that I ought to work on top of a cinder block, and that a small "helping hands" clamping device from Radio Shack was necessary to hold things for me while I heated them.

...And that's actually everything I know!! Each step was a big deal to me -- but once learned, it's just like adding a new media to the art pantry: pastels, acrylics, clay...

Oh -- one other step that was a meaningful hurdle: ordering materials online. It was really weird to be buying something that I'd never touched in person before. Buying "self-skinning flexible expanding urethane foam" from MonsterMakers was where I got over that. I'm going to need to order type 302 stainless steel balls from smallparts.com soon -- I wouldn't be able to if I hadn't already broken the online-buying barrier.

(Not a barrier, but another little bit of learning: Walking around the hardware store looking at nuts and bolts and screws long enough to know the difference between 4-40, 6-32, and 10-24; the difference between a socket cap screw and a machine screw; the difference between brass, zinc, and stainless steel screws... It's been really useful to be able to recognize these things by sight.)

posted by sven | permalink | categories: sculpture, stopmo

May 20, 2006

sculpting: a wingless bird creature

by sven at 12:00 pm

Two weeks ago I started doing a sculpt for a humanoid puppet. I was going to use this sculpt to make my first-ever two-piece mold... However, I've put that project on hold. The mold-making experiment could go horribly wrong -- it'd be foolish to put a huge investment of time into a sculpt that might just get wasted.

Instead of the humanoid, I've gone ahead and made a simpler beastie -- a sort of wingless bird-creature. I think I'm going to name it "buttons", after a raven-critter from Amy Winfrey's wonderful online cartoon series, Making Fiends. (A little homage, y'know?) ...Just one problem: I put too much effort into this sculpt to use it as a first test, either!

Oh well. I'm thinking now that I'll do something ridiculously simple for my two-piece mold test. Like, say, a severed arm. If that goes OK, then I'll go forward with casting "Buttons" in flexible expanding urethane foam.

New invention: A puppetmaking table. Puppets have tie-downs -- screws that come up from underneath the table, fitting into nuts in the feet. This little table has holes in it for tie-downs, so I can easily work with the puppet in a standing position -- but still be able to lift it up or rotate it when necessary. I made a whole series of holes, all 1/2" apart, so the table can accommodate puppets with different gaits.

I think I've come up with a pretty useful tool here... My only complaint: the table's just a little too wide. It's 12" across; 8" probably would have been plenty.

As I understand it, when you're making a puppet from casting materials, you usually create two armatures. A rough one that just holds the clay up while you sculpt. And the good armature, which goes inside the final puppet. I thought I'd be clever and make just one armature...

The one you see above has three twisted strands of 1/16" aluminum armature wire in each leg. The legs are glued into a block of pine with epoxy glue. The feet are metal nuts attached to the wires with plumber's epoxy putty. The nuts are set on top of thin pieces of wood (with holes, so the screws can pass through) -- just to make the soles a bit flatter.

It's a well-constructed armature. But it's not going to work for the final puppet. I can already tell that the leg wires aren't going to be nearly strong enough to pose the puppet's legs. The sculpt wound up being a lot beefier than I expected.

It took three hours to build the armature and puppetmaking table; it took another four to do the actual sculpt. Before adding plastilene, I covered the armature with plastic wrap so it would be protected.

I had a lot of fun... There's something really appealing about working with actual 3D volumes, rather than just 2D representations. I specifically wanted to share the photo above because I was really pleased with how the backs of the legs turned out. Neat shapes.

...And here's the finished sculpt! I used turpenoid with a brush to smooth it out. It's pretty close to what I had in mind. I think I'm beginning to get the knack for this "sculpting" business. ;-)

posted by sven | permalink | categories: sculpture, stopmo

May 12, 2006

kim graham sculpting class

by sven at 12:32 am

I just tonight discovered that Kim Graham is running a "Sculpting the Human Body" class Saturdays 10-2pm, June 3-24. In a heartbeat, I knew: I must be in that class!

Kim's studio is up in Georgetown, WA -- a three hour drive from where I live. But this is a person I'd eagerly travel great distances to learn from.

I met Kim last November at the art marketing workshop by Marty Rudolph. Kim's work is magnificent, gorgeous, astonishing. Her personality is electric.

I am so thrilled to have this opportunity!!

posted by sven | permalink | categories: classes & workshops, sculpture

May 3, 2006

new project: cold foam puppet

by sven at 10:21 pm

After what seems like forever, I finally got back into the studio tonight. I'm starting a new project: making a stopmo puppet with "flexible expanding urethane foam" (cold foam) and a latex skin.

The first step is to make a sculpt out of oil-based clay. Then I'll make a mold out of ultracal 30. Then I'll paint in liquid latex and let it dry. Then I'll put the puppet's armature into the mold, and fill it with the expanding foam.

In making the sculpt, you need an armature to help support the clay. This is NOT the same armature that will be inside the finished puppet. For supporting the sculpt, I used 1/8" thick aluminum armature wire. The base is a piece of wood that I've drilled several holes in, so I can weave the wire through.

I've been experimenting with different types of oil-based clay. From what I've read, the two most popular brands are Roma Plastilina Clay and Chavant Plastiline. Plastilina often has sulfur in it, which interacts badly with latex. Chavant produces an oil-clay called "NSP" (Non Sulphurated Plastine) that's safe; I don't think Roma has a similar product.

According to the Chavant website, there are only two distributors of NSP in Portland: Stephenson Pattern Supply and Lash Quality Molds. These aren't your typical art supply stores; you're only going to know that they exist if you're doing pretty specialized work...

Stephenson Pattern Supply is a wholesaler in the industrial district that has a sign saying they don't accept orders for less than $150 of materials... They mean to scare off browsers; I was fortunate, and they deigned to sell me four pounds of NSP and a bag of ultracal 30 -- despite what the sign said. They're the only place in Portland that sells ultracal 30. [Interesting note to those in the know: This must be where Ralph Cordero shops -- there was a Toxic Mom's Studio sculpture in the lobby!]

Lash Quality Molds is a one-woman operation in an unmarked building way out by the airport. You have to call for an appointment. The owner (whose name I forget at the moment) was a neat person; she gave myself and another fellow a tour of the premises. I saw silicone molds being assembled -- and a monumental sculpture in the back room that was being prepped for casting. The owner recommended that I try J-MAC Classic Clay. It's non-sulphur, and she says the "brown firm" outsells everything else she carries by 80%. Well... I had to give it a try!

Comparing the NSP to the J-MAC, the NSP is more oily. The J-MAC feels more like water-based clay. ...I think I like the J-MAC a lot!!

In all honesy, I've hardly worked with clay at all previously. This is very new to me -- but it's feeling really right.

I do know that I generally like to work reductively -- so I began the sculpt by building up way more clay than I'm going to need. I don't have a drawing that I'm working from; I'm improvising... Happily shaving the lumpy mass into smooth volumes with my one trusty loop tool. I find myself starting with the ribcage, and then everything else evolves from there. The front of the ribcage arcs around to the small of the back; the spine is S-shaped; there's a line that swoops around from the butt to the knee... And so on.

I'm charmed. It's like learning constellations: From the Big Dipper, you arc to Arcturus -- and from Arcturus, spy Spica. :-)

posted by sven | permalink | categories: sculpture, stopmo

April 18, 2006

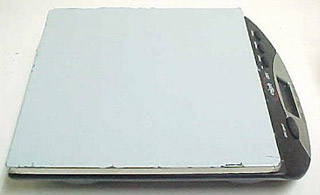

buying a lab scale

by sven at 12:00 pm

It's taken me a long time to get to the point where I can begin experimenting with toxics like resin and urethane foam.

Part of what's held me up is that I've lacked a precision lab scale. I did a bunch of shopping around on Amazon.com and finally found one that is both inexpensive and meets an animator's needs. To all you stopmoes out there, I recommend the 1000 x .1g Precision Lab Table Scale from US Balance.

The standard scale that you'd use for weighing chemicals is the Ohaus 750-SO Triple Beam Scale. This is what I remember using in high school, and (I believe) what Kathi Zung uses in her "Do It Yourself! Foam Latex Puppetmaking 101" DVD. Amazon currently sells the triple beam for $99. I've seen it sold for $150 at other places -- Amazon is offering a good deal. ...But I really wanted a digital scale if at all possible.

So: how to decide what scale to buy? I think there are three factors to consider: How accurate is the scale? How much weight can it accommodate? And what is the cost?

The standard triple beam model is accurate down to .1 grams -- so I decided that whatever digital scale I chose should also be able to measure in .1 gram increments. As for price range, I was hoping to find an option that was no more expensive than the triple beam's normal cost, $150. I decided that if all the digital scales were more expensive than that, then I'd sacrifice convenience and just buy the triple beam.

Fortunately, after a thorough search I found three decent candidates.

The Ohaus SP-401 Scout Pro Digital Scale costs $114.95 -- but can only accommodate 400 grams. One pound equals 453 grams; so the SP-401 can't even deal with four sticks of butter!

The HL2000 HI Digital Scale from A&D Engineering costs $130.23, and can accommodate 2000 grams (four pounds). A bit more expensive -- but much more useful, being able to deal with larger batches of chemicals.

The Precision Lab Table Scale from US Balance can deal with 1000 grams -- but only costs $40!! It's a reasonable compromise in terms of how much weight it can measure (2.2 pounds)... And for $40, I decided I could afford to make a mistake, if this turned out to be a bad purchase.

Luckily, it's turned out to be a very good purchase. So far -- (knock on wood) -- no complaints whatsoever!

posted by sven | permalink | categories: sculpture, stopmo

April 17, 2006

toxic cupcakes

by sven at 9:25 pm

During the past two months I've purchased several new-to-me art materials: ultra-cal 30, RTV silicone, polyurethane casting resin, glass microspheres, and "self-skinning flexible expanding urethane foam". On Saturday I finally had the opportunity to play with all this stuff. Doing small experiments in paper drinking cups, I now have a bunch of odd castings that look like... toxic cupcakes.

What do I plan to do with all these materials? Well, they'll allow me to make molds and castings with a precision that I've never achieved before. So as an artist, I'm interested in them just for the sake of having more techniques at my disposal. However, there are two projects that they may apply to immediately:

Project #1: I want to try making a stopmo puppet with a body cast in foam. Foam latex is the standard for this application. However, foam latex has several problems: it involves 4 chemical components; it requires a dedicated kitchen mixer and oven; it is very vulnerable to temperature/humidity/barometric pressure; and it starts to rot after a few years. ...Contrast this with urethane foam: it only has two components, cures at room temperature, and doesn't rot. --Worth a shot, don'tcha think?

Project #2: I like puppets with heads that are very large in proportion to their bodies. How do I make heads that are light enough so that the puppet won't tip over? Mike Brent suggested that I should try casting my puppet heads in resin. You can get a filler material (such as glass micro-spheres) that will lighten the casting significantly... And as an additional benefit: If you're doing castings, when a puppet breaks you can just cast another!

These materials give off toxic fumes, so I have to work with them outside. However, this is Oregon... It was rainy and windy on Saturday -- so I wound up working on the front porch, manipulating the chemicals inside of cardboard boxes that served as wind-breaks. It worked adequately; but boy do I wish we had a covered driveway!

Please refer to the photo above...

FRONT LEFT: RESIN

The front two "cupcakes" are polyurethane resin. This resin has you mixing part A and part B in a 1:1 ratio by volume, but allows for 5-10% error. For the cupcake on the left, I measured out part A and part B by weight (oops) on my new lab scale. It cured in roughly 20 minutes... It looked sort of like liquid lard congealing, a white clot appearing in the clear fluid. I was disappointed to see tiny bubbles over much of the casting's surface.

FRONT RIGHT: RESIN WITH MICROSPHERES

For the resin cupcake on the right, I tried eyeballing the measurements, and added in the glass microspheres as filler. The bottom-most part of the casting didn't seem as if it was going to cure -- which I attribute to the poor measurements... But the next day, I was surprised to find that the remaining material did finally harden. Conclusion: I prefer not to eyeball measurements. ...The microspheres definitely lightened the material -- and they also smoothed out the surface a great deal. Yay microspheres!

Next steps for exploring resin: The bottles "glug" when I pour them -- I need to see if I can find some screw-on spigots for more precise pouring. I tried painting the resin with acrylic -- but even dry, it wiped off easily. I suspect that resin requires enamel based paints. However, I may be able to use an enamel-based spray primer, over which I could paint acrylics. That, I believe, is how wargamers paint their plastic and metal miniatures -- so I'll have to pick some up at Bridgetown Hobby. ...I'm also interested in trying out some black pigment that gets mixed directly into the resin.

BACK FAR-LEFT: URETHANE FOAM

In the back row on the left is my first experiment with the expanding urethane foam. I was really surprised to discover that it cures in only about six minutes. There were gooey uncured areas at the bottom of the cup, however; I don't know what to make of that. The material feels like a Nerf football -- only a bit stiffer.

BACK MIDDLE-LEFT: URETHANE FOAM ON ULTRA-CAL

The next cupcake is an experiment I did to see if the urethane would stick to ultra-cal 30. I knew that urethane foam has a reputation for adhering to anything -- but I hoped against hope that the self-skinning variety would be different. No luck. This was my first batch of ultra-cal... I eyeballed how much water to add, and it turned out fine. It took a good deal longer to set-up than I expected, though -- around half an hour.

I checked The Prop Builder's Molding & Casting Handbook to see what mold-release it recommended for making urethane foam casts in a plaster mold. It said that PVA (white glue?) could work, but is not recommended. Instead, urethane foam should be cast in silicone molds. This leads us to the pretty blue cupcake...

BACK MIDDLE-RIGHT: SILICONE MOLD, PAINTED FOAM CASTING

The blue cupcake is made of silicone. Silicone is the gooiest stuff I've ever encountered: like wet peanut butter mixed with caulking. I wanted to actually try making a mold with this stuff, so I dangled a wooden sphere from a wire into the paper cup, and then poured in the silicone around it. I was worried that the cold would interfere with curing -- but it seemed to be cured after only six hours, which was listed as the minimum set time. I cut open the silicone with a razor, and bundled it back together with a rubber band. I used the hole where the wire had been as a pour hole, and made an impromptu paper funnel to help channel in the urethane...

The casting was OK, but not great. Air got trapped in the mold, so my casting wasn't perfectly spherical. I guess I need a second hole, so air can escape. The expanding foam was under pressure inside the mold, so it wound up being a good deal denser than I'd like. The surface is relatively smooth, but has pitting that looks like the pores in the skin of your nose. That pretty much terminates my fantasy of doing urethane foam puppets without latex skins. Drat.

One nice thing I'll say about the urethane though: It's really easy to paint. The sphere looks like a cherry because I painted it with red acrylic. The paint doesn't rub or peel off; and it's so flexible, I question whether you'd even need PAX paint if you were doing an all-urethane puppet.

BACK FAR-RIGHT: LIQUID LATEX ON UNTRA-CAL

The cupcake on the far right is another ultra-cal test. I did a quick google on the material, and discovered that 38 parts water for every 100 parts ultra-cal is recommended. This batch seemed to have a little water left over; now that I think about it, I wonder if it's because I measured by weight instead of volume? ...Even so, it set up. I tried painting some liquid latex on top; latex (unlike the urethane) comes off easily.

Conclusion: It looks like my next puppet will be made from flexible urethane foam with a latex skin, all cast in an ultra-cal 30 mold. The foam seems to be fluffiest when it has ample room to escape -- so I'll need to make vent holes in the puppet's feet. I have some Pro Adhesive (a Prosaide knock-off) for making PAX paint...

So I guess at this point I have everything I need to get started!!

posted by sven | permalink | categories: sculpture, stopmo

April 6, 2006

building sets with insulation foam

by sven at 6:00 pm

Back on March 15 I made my first foray into set-building. (I've been meaning to write about this for a while!)

From what I've read online, it seems that one of the most versatile materials for making stopmo sets is insulation foam -- so I started there. I used 1" thick pink Dow insulation foam-board to create a 24"x15" stone wall.

I hacked into the foam with a steak knife to create an irregular surface. Then, I painted the entire thing with black (acrylic) gesso. On top of this basecoat I dry-brushed three layers of acrylic: burnt umber, a gray, and finally a very pale gray. I was originally trying to create the look of a cave wall. I don't think I got that. Maybe a cliff face, maybe granite that's been roughly mined...

Even so -- for a first try, I'm very pleased with the results. Here's what I'll need to explore next...

- While the surface texture is good, it's still just a flat wall. I want much more depth in my sets -- hallways and landscapes, etc., where there can be a foreground, midground, and background. ...I always think of Peter Greenaway's cinematographer Sacha Vierny as someone I'd like to emulate in this regard.

- The lighting is flat and lifeless. I've ordered some par cans and gels, so I can start experimenting with more dynamic lighting set-ups. A cave environment, I think, needs some blues and reds.

- I'm increasingly curious to try a hot-wire foam cutter. There's a local hobby store that carries them -- but I'll want to do some further online research before I purchase.

posted by sven | permalink | categories: sculpture, stopmo

March 22, 2006

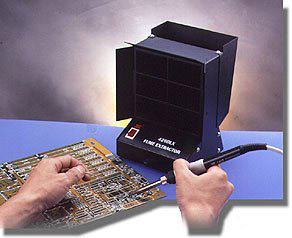

tutorial: desktop ventilation

by sven at 4:55 pm

Many of us who are working on stopmo puppets labor in dungeon-like basements. Although we know that we should have "good ventilation" while working with toxics, it just doesn't seem possible -- so we play dumb. This is not OK!

desktop ventilation system In this post I'll show you how to build your own desktop ventilation system. Please -- if you work with materials such as super glue, epoxy glue, epoxy putty, barge cement, turpenoid, acetone, or soldering wire while making your puppets -- strongly consider making a ventilation system siimilar to this one for yourself!

a temporary solution It takes a while to get new a ventilation system set up. In the meantime, at least put a fan in your window.

[Addendum: And be sure that the fan is sucking air out of the room, rather than blowing air in.]

When you're working on something toxic at a desk, you usually have your face right over the nasty stuff. Opening a window will help keep the fumes from building up in the room -- and using a fan to suck the fumes out will help even more. If you're just using a fan, though, you're still breathing in the fumes as they rise up from your work.

What you want is for the fumes to be actively sucked away from you, in a way where they don't go past your face as they escape.

Paasche spray paint booth My first strategy for good ventilation was to purchase a Paasche hobby shop spray paint booth ($269 before shipping). But unfortunately... I HATED it!

The spraybooth takes up my entire desk. And although it's collapsable, it is not nearly as easy to set up as I had initially hoped.

the huge motor Storing this thing is another problem. Look at how huge that motor is! ...Much discouraged, I wound up returning the spray booth to the store where I had purchased it.

venting fumes outside One thing about the spraybooth solution that did work well was the way that I vented it out the window. The insulation foam doesn't have to live there forever; I just pop it out of the window between work sessions. [In this picture it looks like there's a crack of light between the foam and the sliding window -- but I realized later on that the foam could fit even more snugly if I just pushed it into the window frame a little farther.]

...After finally admitting to myself that the spraybooth wasn't going to work out, I resumed research. Luckily, right around this time I was exploring soldering. I stumbled upon this useful quote on the Art Glass Association's website:

"Most fluxes contain zinc chloride that is harmful to the skin and eyes, and toxic if ingested. Read the labels on all chemicals you use for safety precautions. Flux also produces fumes when it is heated (as in soldering) and you need to work in a well-ventilated area.

Well-ventilated means MOVE THE AIR - DON'T JUST OPEN A WINDOW. There are small, portable fume removers made specifically for eliminating flux fumes, available through your local stained glass retailer. If you find that you are getting frequent headaches or sinus problems, you may be breathing fumes. One rule of thumb - if you can smell what you're working on, you probably need to move the air a bit more, or invest in a fume remover."

the Edsyn "Fuminator"

the Xytronic 426DLX This site on soldering safety recommended the Edsyn Fuminator for soldering fume extraction. That was the most explicit product recommendation I could find. Hunting around on Amazon.com and elsewhere, I found that the Fuminator's main competition seems to be the Xytronic 426DLX fume extractor. ...So the problem became how to choose between the two.

What's important here? First of all, we need something small that won't take up a lot of desk space. Folks doing soldering (unlike folks doing airbrushing) have this same need -- which is why fume extractors are also a good option for puppet-makers. Second, we need something that has powerful sucking capabilities.

Airflow is measured in CFM (Cubic Feet of air per Minute). According to this Fuminator product info sheet, "the maximum air flow with both filters installed is 21 cfm." According to this Xytronic product info sheet, the 426DLX's "max. air volume" is "95/115 CFM". So, although the Fuminator has a sexier design and is more expensive ($79.95 at Amazon.com), it appears that the Xytronic 426DLX is really the better purchase for our purposes.

[This write-up on the Paasch spray booth says that it "provides approximately 80 to 100 LFM air movement." That's Linear Feet of air per Minute... These companies certainly don't make comparison-shopping easy!]

Xytronic 426DLX - front At present, the Xytronic is being sold for $59.95 at Amazon.com. With shipping and handling, it cost about $64, and took about a week to arrive.

One thing that I did not 100% understand when I ordered the Xytronic is that tabletop fume extractors aren't intended to be attached to a hose for venting. The fan sucks air through a carbon filter, and simply vents out the back. This raises a question: Would it make more sense just to buy a simple fan? I don't think so. What we need is a very small, very powerful fan -- which is what the fume extractors have. It's hard to find plain fan with these qualities.

...And, even though the fume extractors weren't built to attach to ducting, I feel it's easier to attach ducting to these than it would be to a fan. So I'm sticking with the Xytronic.

Xytronic 426DLX - back As you can see here, the Xytronic has a plate on its back that directs air upward and out of a slot on top of the device.

removing the back Removing the back plate was a simple matter of taking out a few screws. In order to maximize air flow, I also chose to remove the filter. The filter is supposed to be replaced every month, so the device is built to make removal of this part easy.

cutting the insulation foam What we need now is an adaptor, so we can attach ducting. I started by measuring the back of the Xytronic, and then cutting out a square of insulation foam that matched its dimensions.

inserting duct adaptor If you go to Home Depot and look in the aisle where they carry air ducting supplies, you should be able to find an adaptor that looks like the one above. Trace the adaptor's outline onto the foam, and then cut this circle out with a steak knife. Trim as needed so you can fit the adaptor snugly into the hole.

attaching cardboard This next step is mostly just to disguise the ugly pink foam. I measured the sides of the foam square, and cut out rectangles of cereal box cardboard to cover them. The cardboard is wider than the foam on three of the sides so we can easily fit it around the Xytronic.

assembly Press the pink foam square against the back of the Xytronic. The cardboard lips should wrap around the top and sides of the device. Now attach this adaptor that you've made onto the fan using clear packing tape. Seal up any cracks you notice where fumes might escape.

duct and hose clamp The ducting is the same kind that comes out the back of a clothes dryer. Attach it to the tin ducting adaptor using a hose clamp. The foam that sits in the window frame also has a tin adaptor in it, and the ducting is attached with a hose clamp there, too.

completed ventilation system tucked away Here's the completed desktop ventilation system, tucked away at the side of my desk. The ducting is still a bit awkward -- but it's a far better solution than the spraybooth.

smoke test But wait! There's one more thing that you need to do. You need to understand the range at which the ventilation system is effective.

Turn on the Xytronic. Light a candle, and then blow it out. If everything is working properly, the smoke will be sucked into the ventilation system. OK -- now lay down a ruler. How far away can you pull the candle before the smoke just wafts up into the room?

I found that the suction is only effective when the candle is within 6 inches of the fan. That's not really very far -- but remember, this system is designed to deal with small jobs, like when you're using epoxy glue or soldering. Be mindful of the range when you work -- and even when the Xytronic is turned on, be sure to wear a respirator rated for organic solvents for additional protection.

Good luck, and play safe!

posted by sven | permalink | categories: sculpture, stopmo

January 30, 2006

sculpting: new test snippets

by sven at 12:30 am

I've done a bunch of little test snippets with different sculpting materials this past week. Lots of things to show you!

papier mache mash The papier mache mash I wrote about on Jan. 23 has finally dried. I think it took about five (maybe six) days. The stuff that I baked turned dark and tough; it reminds me of a chew toy you'd give to a pet dog... I'll never try that again. The unbaked stuff turned a pale gray; it has potential. I'm thinking about how I could use it for stopmo animation sets.

insulation foam; "Sculpt It!"; Foam Putty; Creative Paperclay; clay and wood flour mix Here are several test "fingers" I made using different materials. From left to right:

- insulation foam

This is a bit of carved insulation foam without anything on it. The rest of the tests involve spreading different substances on top of one of these. - "Sculpt It!"

This feels like a high-grade Play-Doh; sort of soapy, very slightly springy. When I try to put it through the pasta machine, it becomes flakey. Loop tools work poorly. It smooths easily with fingers. It starts feeling dry to the touch after 10-15 minutes, but remains workable longer. It shrinks while drying; since it was applied over a foam core, this made it crack. - Foam Putty

I found this at a model train store. It has a very fine powdery grain, like spackle. It has the consistency of very light frosting. It can be spread, but is impossible to sculpt; it's only good for filling in cracks in pieces of foam, I think. It didn't crack while drying. - Creative Paperclay

The fiber content is very fine. Smoothing with fingers works OK; water helps. Loop tools work pretty well, but leave a rough grain that needs smoothing; sometimes using the loop tool leads to crumbling. Doesn't go through the pasta maker well. Doesn't adhere to the foam core easily. Cracked while drying. - air-drying clay mixed with wood flour