you are here [x]: Scarlet Star Studios > the Scarlet Letters > casting in urethane foam

<< before

foam latex - first attempt

after >>

lsgl: beacon mock-up

April 12, 2007

casting in urethane foam

by sven at 8:00 am

On Monday and Tuesday I did my first casting using foam latex. That makes this an opportune moment to mention that last month (3/17) I also finally got around to trying out flexible expanding urethane foam.

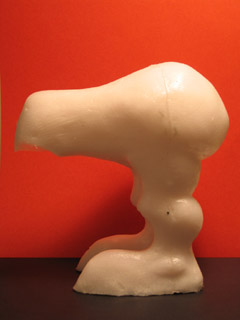

I got this particular urethane from MonsterMakers.com. It's the self-skinning variety. Like with the foam latex experiments, I decided to use the two-part mold that I made for the flightless bird sculpt last year. Since my interest right now is in the material itself, I didn't bother to make a puppet armature.

I was hoping to be happily proven wrong... But as expected, the casting turns out to be too tough for animation purposes. It's like a Nerf football -- but with skin that's almost as tough as a basketball in places.

Urethane foam (I believe) has some of the same constituent chemicals as super glue. It'll stick to just about anything. So, before putting it into my mold, I painted the mold walls with liquid latex.

[That's a trick I read about in the StopMotionAnimation.com handbook... Although, re-reading the article now, I see that the latex trick is actually intended for non-skinning urethane. Oops.]

For the first pour, I mixed up 100 grams of component A and 50 grams of component B.

At first, it looked like I'd done a good job of estimating how much foam to mix. The material foamed up and came out of the feet... But then, to my surprise, it sank back down a ways.

I mixed up a second batch to fill in the soles of the feet: 20 grams of component A, 10 grams of component B. I figured that ought to be more than enough.

When I filled the feet, the foam rose up -- and then sank down again. Hm. The foam self-skins when it's against a mold wall... But I guess its surface tension breaks when in the open air. Curious.

It took some work to get the casting out of the mold. Definitely an effort -- but not terrible.

The latex skin didn't hold up very well. Particularly at the seam between the mold halves.

I just went ahead and peeled off all the latex. It came off easily. Unfortunately, the brush marks (from when I'd brushed the latex into the mold) all transfered to the urethane.

That being the case, I'm thinking that if I ever do flexible expanding urethane foam again, then I'll probably just use vaseline as my mold release -- and skip the latex.

The final product isn't bad -- if it were intended to be a static sculpture. The main flaw is a small bubble that got trapped at the end of the beak. [I probably ought to have rotated the mold.] The seam line is minimal.

Conclusion: This particular brand of urethane is useless for puppets -- unless, perhaps, they're very thin puppets. The material is just too tough.

posted by sven | April 12, 2007 8:00 AM | categories: stopmo